LOXY® REX 14501

Key Features |

|||

| Property | Colour | Wash temp | Application method |

|---|---|---|---|

|

|

|

|

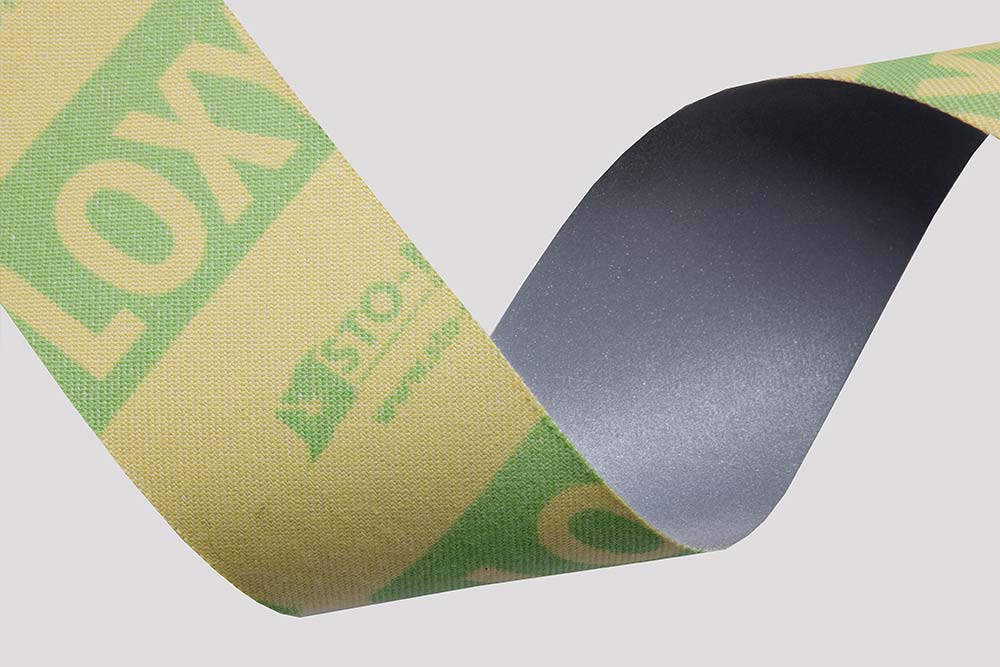

Flame retardant reflective tape

Key Features |

|||

| Property | Colour | Wash temp | Application method |

|---|---|---|---|

|

|

|

|

Key Features |

|||

| Property | Colour | Wash temp | Application method |

|---|---|---|---|

|

|

|

|

Key Features |

|||

| Property | Colour | Wash temp | Application method |

|---|---|---|---|

|

|

|

|

LOXY® REX 14501 brings the powerful flame retardant properties of LOXY® reflective materials and combines them with the long lasting durability for complete industrial washing. This ensures that not only will the LOXY® REX brand reflective materials outperform other reflective tapes but they will outlast and outshine after repeated heavy duty use by fire rescue crews, electrical workers and more.

Our reflective tape LOXY® REX 14501 is specifically designed for Multinorm garments, which are intended to meet multiple safety standards in various industries.

Multinorm Suitability: Tailored for garments that need to adhere to Multinorm standards. Multinorm clothing typically requires protection against static electricity, chemicals, flame retardancy, and high visibility.

Application in various Industries: Multinorm garments find usage in several industries, including engineering, metallurgy, petrochemicals, chemicals, mining, and plastic processing. These industries demand high safety standards due to their hazardous nature.

The specific requirements for Multinorm clothing, such as protection against static electricity, chemicals, and flame retardancy, necessitate materials like LOXY® REX 14501, which provide both safety and visibility. The reflective tape’s suitability for these garments helps enhance visibility in workplaces where safety is crucial, ensuring compliance with safety standards across multiple industries.

Sew-On, please find corresponding section in “LOXY® Product Guide” for further instructions.

In general, store reflective tapes in cool and dry places. Please see “LOXY® Product Guide”.

| Domestic wash: Max 60°C, duration 60 minutes. Refer to detergent manufacturer for right dosage and products for your water hardness. | |

| Industrial wash: Max 75°C, ISO 15797, table 4.8. | |

| Tumble drying: Max 160°C | |

| Tunnel finishing: Max inlet temperature 155°C | |

| Dry cleaning: Perchloroethylene recommended. | |

| Ironing: Medium iron, not steam. | |

| Bleach: Not recommended. |

| Total thickness | 510 micron |

| Color | Silver |

| Backing fabric | 100% Cotton |

| Roll length | 50 meters / 55 yards |

EN ISO 20471 / ANSI /ISEA 107 (ISO 15797 & ISO 6330)

EN 11611 and EN 11612

ISO 14116 (Index 3)

EN 469

ISO 3175

EN 1149-5

Oeko-Tex®

NFPA 1971 / NFPA 1977 / NFPA 2112

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Product Enquiry