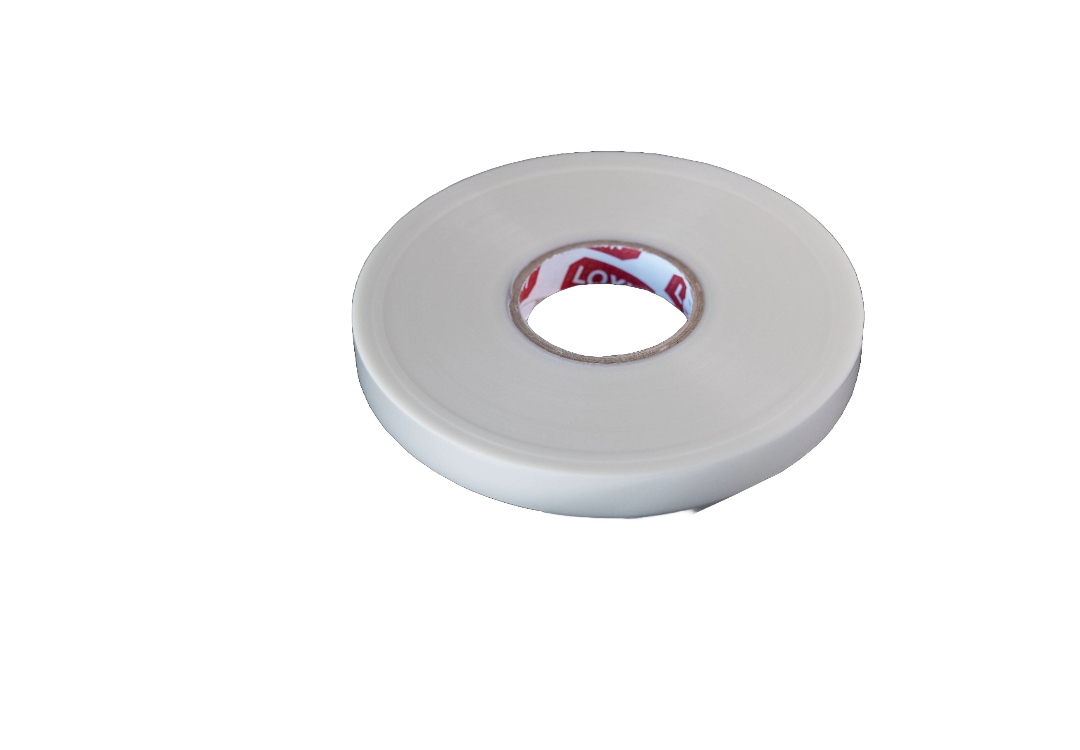

LOXY® Seal LS800

Key Features |

|||

| Property | Colour | Layers | Wash temp |

|---|---|---|---|

|

|

|

|

Two-layer seamsealing tape for FR fabrics

Key Features |

|||

| Property | Colour | Layers | Wash temp |

|---|---|---|---|

|

|

|

|

Key Features |

|||

| Property | Colour | Layers | Wash temp |

|---|---|---|---|

|

|

|

|

Key Features |

|||

| Property | Colour | Layers | Wash temp |

|---|---|---|---|

|

|

|

|

At Loxy, we’ve spent years refining our line of seam sealing tapes to become the premier solution for completing the waterproofing elements of any garment.

Our LS800 seam sealing tape series is a 2 layer, 100% thermoplastic polyurethane tape. It is designed to suit a wide range of garment styles including FR fabrics.

By using a 100% thermoplastic polyurethane seam sealing tape, you can provide a reliable waterproof barrier without compromising the flame-resistant qualities of the fabric.

Our FR seam sealing tape series are a valuable solution for manufacturers and industries seeking to enhance the performance and safety of their FR garments while maintaining waterproofing capabilities.

Applications

Our seam sealing tape is well-suited for a variety of applications, including military gear, industrial workwear, and outdoor apparel, where both performance and environmental considerations are key factors.

Domestic washing approved according to the Loxy Product Guide. Industrial washing approved using gentle methods.

Proper inventory control will ensure that your tape maintains optimal shelf life (up to 2 years)

Application will vary depending on a number of factors including fabrics, machinery involved, working conditions and more. Before use in bulk production, each fabric should be individually tested to ensure proper application. Based on your fabric samples, we can advice for the best tape application.

| Hot Air Temperature: | 490–580°C / 914–1076°F |

| Hot Air Pressure: | 0,065–0,10 MPA / 0,65–1 Bar |

| Speed: | 2,0–8,0 m/min |

| Roll Cylinder Pressure: | 3,0–5,0 kg/cm2 |

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Product Enquiry